DISASTER SAFETY AI SOLUTION

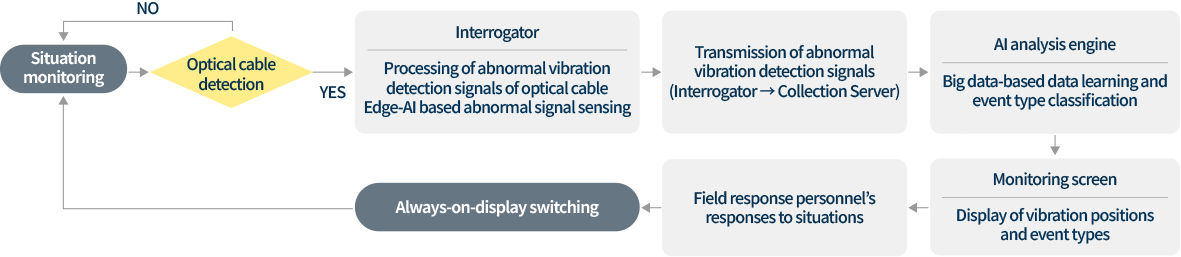

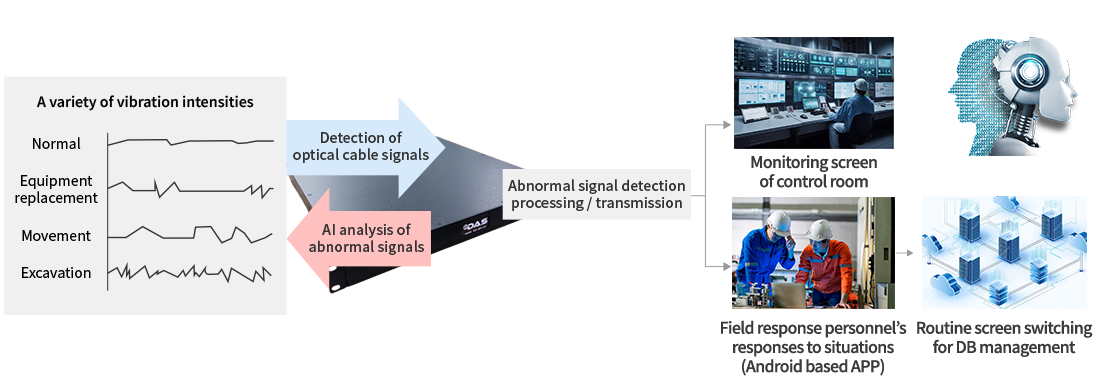

Distributed optical sensors (optical cables for communications) are installed in measurement sections to continuously measure acoustic vibrations,

temperature, and other parameters. These collected data are analyzed and monitored in real time to detect any anomalies.

KOREA

Public Procurement Service Innovation Product Certification Completed

KOREA

KC Certification completed

USA

FCC Certification completed

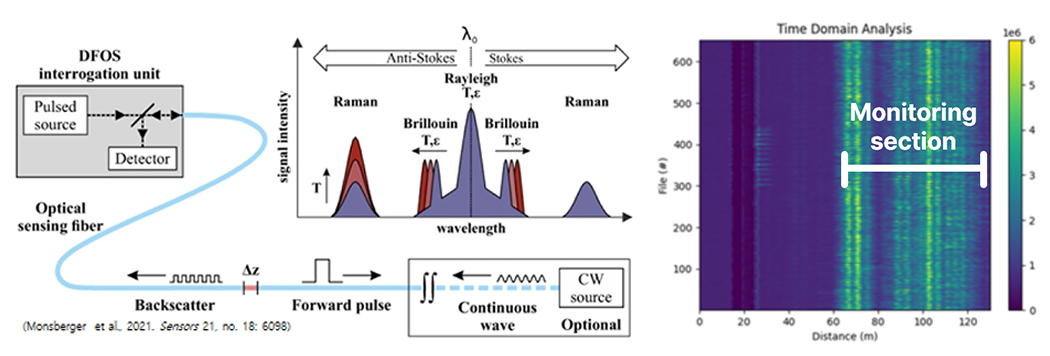

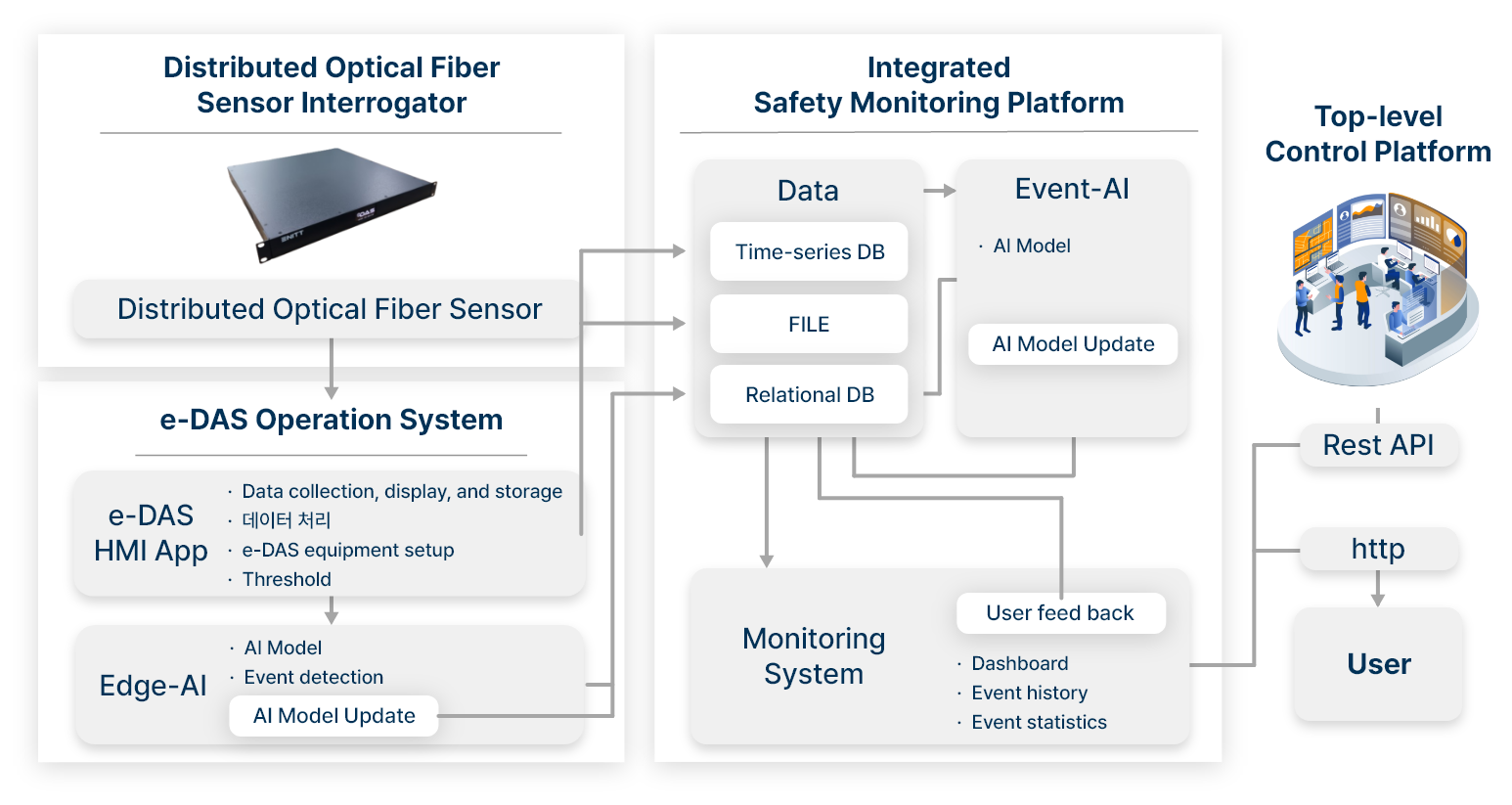

e-DAS uses an optical fiber cable as sensors to measure the distribution forms of physical quantities (acoustic vibrations, temperature, deformation, etc.) across the entire sections of the optical cable (sensor). Based its generated optical signals, the system receives and analyzes backscattered light signals generated by the optical cable (sensor) to measure physical quantities at different points along the cable.

By measuring physical quantities such as acoustic and vibration changes over long distances and continuous or specific sections, this product overcomes the limitations of traditional monitoring systems. It helps to prevent safety accidents by detecting abnormal vibrations in real time across various facilities and structures.

Sensor

Optical cable

Data trend

measurement

Optical measurement

system(e-DAS)

Classification of measured data

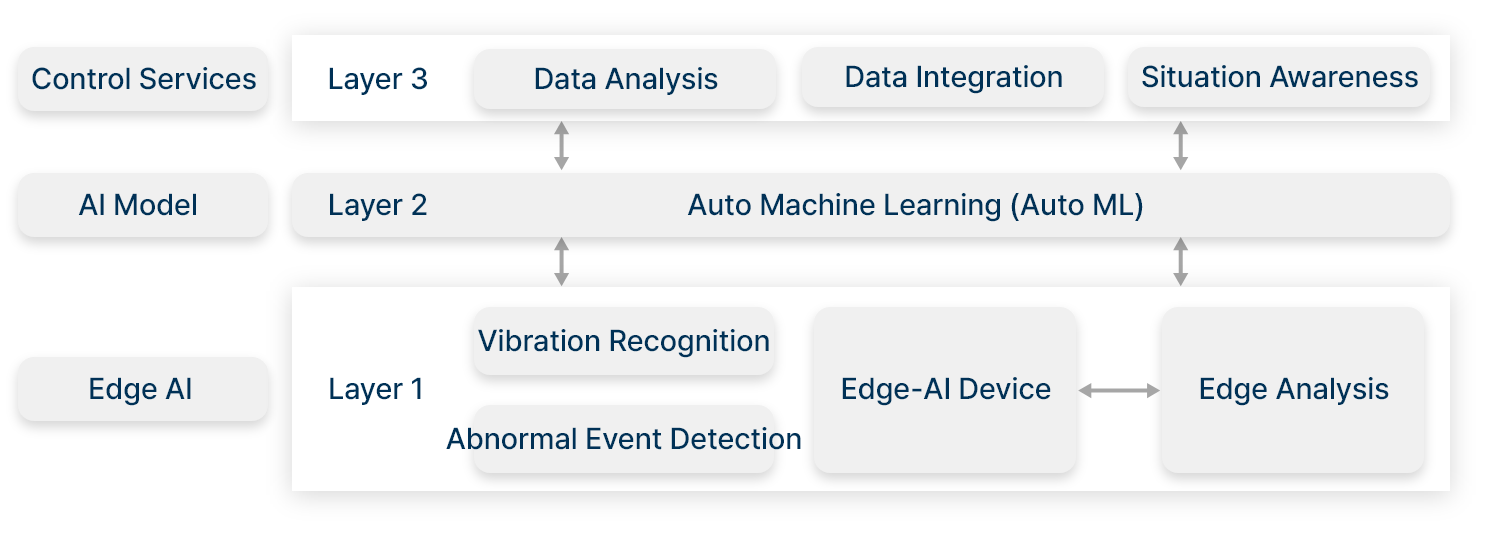

Edge AI analysis

Real-Time status detection

Monitoring

[System Configuration Diagram]

Distributed optical acoustic vibration measurement system based on the phase type enabling long-distance fine vibration sensing, compared to amplitude type

Real-time monitoring of structural anomalies for each distance and interval with the use of acoustic vibration change data

The only product in the country, capable of continuous long-distance measurement (approximately 50 km) without blind spots

One measurement system supports up to 4 channels (based on e-DAS)

Cost saving for initial setup by using an existing optical fiber cable for communications as a sensor (changeable according to on-site conditions)

Zero impacts of communication restrictions, dust, and humidity due to immunity to EMI (electromagnetic interference)

Reduces the time to transmit data to the cloud, enabling real-time high-speed data processing and analysis

Ensures proactive response time for safety accidents by quickly detecting and classifying risks at the edge

Secures over 90% AI classification accuracy through repetitive learning of Edge Device

Capable of detecting and classifying risk situations based on complex physical quantities (vibration, temperature, strain, etc.) delivered to optical sensors

| Maximum Measurement Distance | 25km~100km |

|---|---|

| Position Accuracy | 1m–10m (varies with maximum measurement distance) |

| Number of Channels | 1ch~4ch |

| Line Width | <15KHz |

| Pulse Repetition Rate | 1~20KHz |

| Optical Amplification Rate | >20dB |

| Frequency Measurement Range | Above 1 kHz |

|---|---|

| Central Wavelength | 1550 ±1nm (check Seed Laser) |

| Pulse Width | 50~200ns |

| Optical Output Range | 10~20dBm |

| Data Transmission Speed | >1Gbps |

| - | - |

| Optical Cable Terminal | FC/APC |

|---|---|

| Ethernet | - |

| USB | - |

| RS232(DB9) | Config setting |

| Display | 2.4inch OLED |

| Product Size | 435 x 41.6 x 456.4mm |

|---|---|

| Weight | 4.21Kg |

| Operating Temperature | -10 ~ 40℃ |

| Operating Humidity | 10 ~ 90%, Non-condensing |

| Storage Temperature | -40 ~ 80℃ |

| Laser Safety Class | Class 1 |

|---|---|

| Product Certification | KC, FCC |

| - | - |

| Operating Voltage | 100~230 VAC |

|---|---|

| Operating Voltage Frequency | 50~60 Hz |

| Power Consumption | 30.8W (typical) |

| Rack | 19" Rack 42U |

|---|---|

| DAQ Unit | DAS signal data collection, analysis, and processing |

| Storage | DAS signal data storage |

| DAS signal data deep-learning analysis | Analysis Server |

| Visualization Server | Visualization of DAS analysis information |

|---|---|

| UPS | Uninterruptible Power Supply |

| L2 Switch | L2 Network Switch |

| KVM | KVM for Server |

* The system configuration may vary depending on the purpose and environment.

Underground

Utility

Tunnels

Railway Tracks

Conveyor Belts

Power

Generation

Equipment

Transport Pipelines,

Pipelines

IntrusionM

Monitoring